传统合金由一种基本元素和少量元素组成

随着现代工业的发展,新型的“多主元合金”(Multi-principal element alloys, MPEAs)应运而生[1~4]

多主元合金由三至四种元素按等原子比或近等原子比生成中熵合金(Medium entropy alloy, MEA),五种及以上主要元素生成的合金称为高熵合金(High entropy alloy, HEA)[5]

多主元合金具有高熵效应、缓慢扩散效应、晶格畸变效应和鸡尾酒效应[1, 2],因此多主元合金在高温、强辐照、高摩擦以及强腐蚀等极端领域有广阔的应用前景[6~13]

多主元合金中不同组元原子半径的差异产生严重的晶格畸变,阻碍位错的运动

因此,晶格畸变是多主元合金固溶强化的关键因素[14~16]

VCoNi中熵合金具有典型的晶格畸变效应,其抗拉强度接近1 GPa,伸长率约为55%,实现了优异的强韧化性能协调[16, 17]

其原因是,V原子显著增大了原子键距的波动,严重的晶格畸变使位错移动需要的晶格摩擦应力显著提高[16]

与传统合金类似,添加间隙原子可产生间隙强化和第二相强化[18, 19]

碳(C)是应用最多的间隙原子之一

在CoCrNi中熵合金中加入C(0.75%,原子分数),可使其强度提高且保持着75%左右的延伸率[20]

其原因是,C产生的间隙固溶强化提高了合金层错能,从而延缓孪晶的产生并减小孪晶层的厚度

这些细小的孪晶组织,可延缓塑性失稳并显著提高合金的加工硬化能力

在FeCoNiCrMn高熵合金中加入少量的C(0.1%,原子分数),可使其在变形过程中产生更高密度的位错和后续退火中孪晶界的比例显著降低,因为C原子使合金的层错能增大[21]

Fe49.5Mn30Co10Cr10C0.5高熵合金的低温(77 K)抗拉强度(1300 MPa)[22]比室温显著提高,且具有出色的延伸率(50%)

其原因是,C原子产生的间隙固溶强化和合金层错能的降低提高了晶格摩擦力,使位错滑移方式由波浪滑移转变为平面滑移

在合金的变形和热处理过程中发生的织构变化使样品产生各向异性,因此研究其织构演变至关重要

例如,冷轧处理后的CoCrNi中熵合金产生以Brass为主的形变织构,而热轧样品则产生明显的α取向且Brass织构强度降低;热处理后CoCrNi合金中的再结晶晶粒仍保留大量的形变织构组分,即以α取向为主的再结晶织构[23]

Bhattacharjee等[24]研究了CoCrFeMnNi合金冷轧和退火后的织构演变,发现冷轧90%后出现强Brass型织构,而再结晶织构中保留了Brass变形织构组分,但是新形成的S织构比Brass织构更强

对于力学性能出色的多主元合金,其在摩擦服役条件下的服役性能受到极大的关注

C原子掺杂使CoCrFeMnNiC x 合金的摩擦磨损性能提高[25],因为生成的硬M7C3碳化物(M主要为Cr、Fe和Mn)使磨损表面的分层行为减弱

用激光熔覆技术在45钢表面制备的CoCrFeMnNiC x 改性层[26],随着C含量由0提高到0.09涂层的摩擦因数降低而耐磨性能提高

其原因是,析出的硬质碳化物M23C6保护了磨损表面

在Fe50Mn30Co10Cr10基体中添加B4C陶瓷颗粒使其具有比基体更高的摩擦磨损能力[27],因为B4C颗粒在基体材料中产生弥散强化和细晶强化,使磨损率和摩擦系数显著降低

鉴于此,本文在VCoNi中熵合金中添加不同含量的C原子制备(VCoNi)100-x C x (x=0,0.1,0.4,1和2.8)中熵合金,系统研究C含量对VCoNi中熵合金的微观组织演变、力学性能以及摩擦磨损性能的影响

1 实验方法

实验用原料为高纯粉末V、Co、Ni和C(其纯度均高于99.9%)

以氩气作为保护气体,用真空非自耗电弧炉熔炼(VCoNi)100-x C x (x=0,0.1,0.4,1和2.8)样品

根据添加C原子的比例,将样品命名为CX

先将金属粉末充分混合,然后压成直径为10 mm、高约为10 mm的圆柱体

将圆柱体放入真空非自耗电弧熔炼炉的水冷铜坩埚中进行熔炼,为了保证样品的均匀性,每个样品至少翻转重熔4次,得到铸态样品

随后将铸态样品在1000℃保温2 h后进行热压缩变形(变形量45%),再将热压态样品在1000℃保温2 h后水淬,得到均匀态样品

用电火花线切割机将均匀态样品切片,然后进行室温轧制变形(变形量70%),并将其在1000℃保温1 min后水淬,得到再结晶态样品

使用配备有EDS分析仪和EBSD探头的ZEISS SIGMA HD场发射扫描电镜(SEM)观察样品的微观组织及元素分布

先用砂纸将SEM样品水磨至3000#,再进行电解抛光

电解抛光液的成分为高氯酸和乙醇(体积比1∶9),抛光温度约为-30℃

电解抛光时将样品接直流稳压电源的阳极,用不锈钢作阴极,在电压为20 V、电流为0.25 A条件下

电化学抛光约50 s

用Channel 5后处理软件分析EBSD数据

用万能拉伸实验机测试室温拉伸性能,拉伸应变速率为3 mm/min,试样标距长度45 mm,宽10 mm和厚2 mm,其形状似“狗骨状”

使用圆盘式磨损试验机进行室温摩擦磨损实验,试样的长度为20 mm、宽为10 mm、厚为2 mm,使用直径为6 mm的Al2O3球作为摩擦副,旋转半径为3 mm,转动速度为200 r/min,载荷为10 N,测试时长为30 min

用Bruker白光干涉仪测量摩擦磨损样品磨痕的三维形貌,使用Vision 64软件处理干涉仪数据得到磨损三维形貌和磨损体积

使用Thermo-Calc软件(Version 2020a)进行CALPHAD计算并根据热力学数据库TCHEA 4[28],绘制出(VCoNi)100-x C x (x=0,0.1,0.4,1和2.8)样品的相含量随温度变化,以分析其主要相结构

2 实验结果

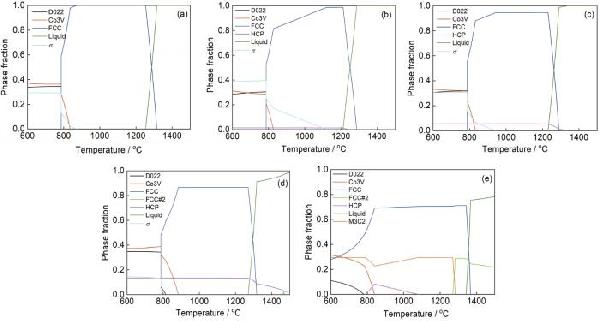

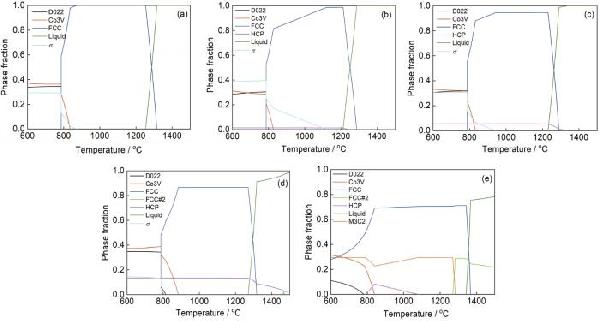

图1给出了(VCoNi)100-x C x (x=0,0.1,0.4,1和2.8)的相含量随温度变化

x=0时(图1a),高温相区(870~1253℃)的结构为单相FCC,在低温相区(600~869℃)出现金属间化合物Co3V、D022(Al3Ti型)和σ相

x=0.1时(图1b),合金的熔点略有降低(1212℃),σ相的析出温度升高(1120℃),在1238℃开始析出少量HCP相

x=0.4时(图1c),合金的熔点提高(1230℃),σ相的析出温度降低(940℃),HCP相的析出温度升高(1330℃)且其含量提高

x=1时(图1d),合金的熔点继续提高(1270℃),在温度区间1460~1500℃析出FCC相,且随着温度的降低出现HCP相(1472℃)、σ相(787℃)

x=2.8时(图1e),合金的熔点提高到1343℃,σ相消失,在1290℃析出M3C2型(M=V、Co)碳化物,FCC相区扩宽(1269~1500℃),HCP相区变窄(786~1080℃)

这表明,随着含C含量的提高,金的熔点呈现升高的趋势,HCP相的含量先提高后降低,σ相的含量逐渐降低

图1

图1(VCoNi)100-x C x (x=0,0.1,0.4,1和2.8)的相含量随温度的变化

Fig.1Phases fraction as function of temperature for (VCoNi)100-x C x (x=0, 0.1, 0.4, 1 and 2.8) samples (a) C0; (b) C0.1; (c) C0.4; (d) C1; (e) C2.8

图2给出了均匀态(VCoNi)100-x C x (x=0,0.1,0.4,1和2.8)样品的SEM形貌

C0(图2a)、C0.1(图2b)和C0.4样品(图2c)的晶粒均呈等轴晶形态,退火孪晶呈板条状,平均晶粒尺寸分别为40 μm(图2a),32 μm(图2b)和21 μm(图2c)

C1样品(图2d)的晶粒呈等轴晶和胞状晶,平均晶粒尺寸为28 μm,在等轴晶中也观察到退火孪晶

C2.8样品(图2e)的晶粒呈胞状形态,没有退火孪晶,平均晶粒尺寸为49 μm

同时,随着C含量的提高,均能观察到不同形态的第二相颗粒;C0.1、C0.4和C1样品中的第二相以棒状和颗粒状形态为主;而C2.8样品中的第二相则呈条状、棒状和颗粒状

图2

图2均匀态(VCoNi)100-x C x (x=0,0.1,0.4,1和2.8)的SEM照片

Fig.2SEM images of as-homogenized samples: (a) C0; (b) C0.1; (c) C0.4; (d) C1; (e) C2.8

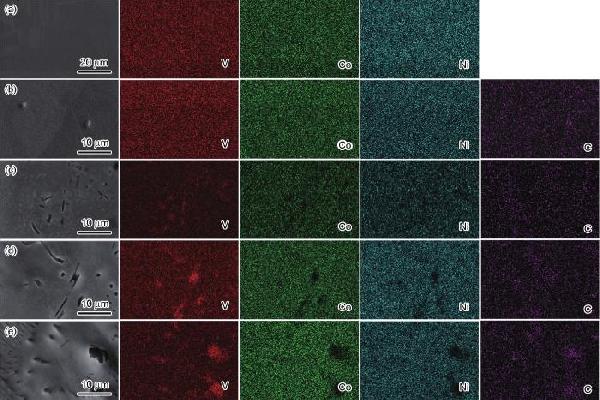

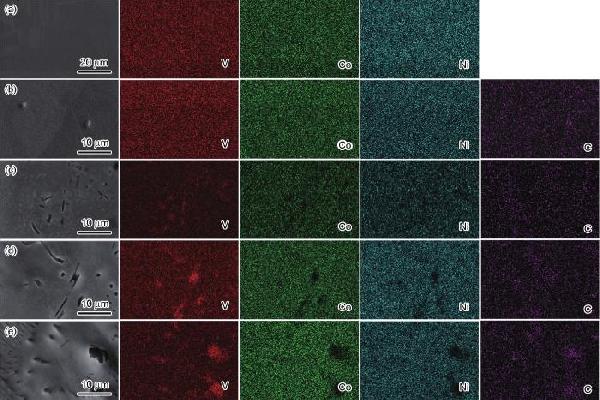

图3给出了均匀态(VCoNi)100-x C x (x=0,0.1,0.4,1和2.8)样品的EDS面扫分布图

图3a~b表明,C0和C0.1样品中的V、Co和Ni原子分布均匀

图3c~e表明,C0.4、C1和C2.8样品中的V和C原子明显富集,且主要集中在第二相,为钒碳化合物

图3

图3均匀态(VCoNi)100-x C x (x=0,0.1,0.4,1和2.8)的EDS面扫分布

Fig.3EDS element distribution of as-homogenized samples (a) C0; (b) C0.1; (c) C0.4; (d) C1; (e) C2.8

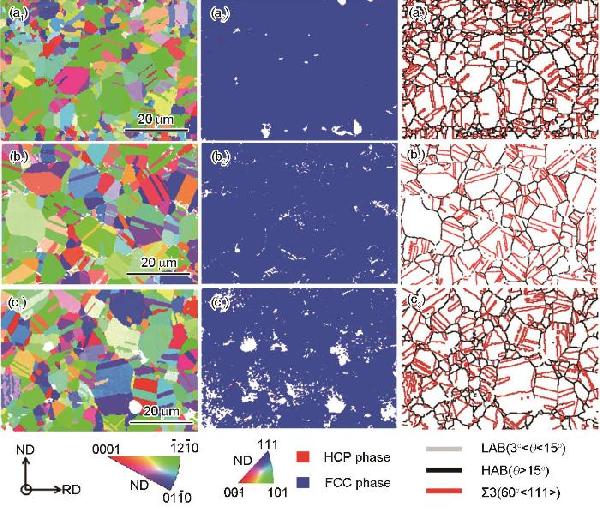

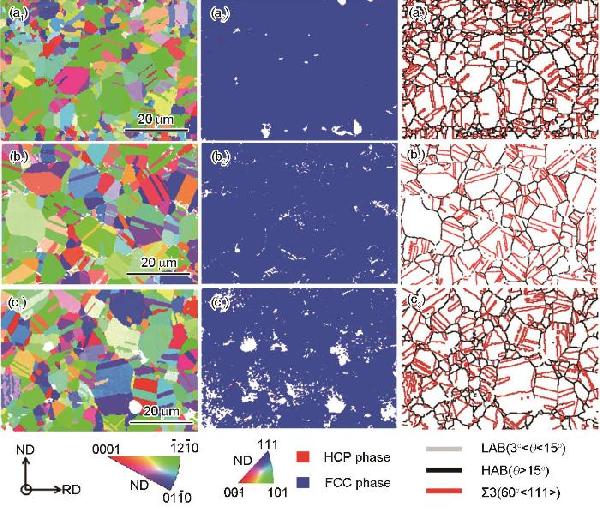

图4给出了均匀态(VCoNi)100-x C x (x=0,0.1,0.4,1和2.8)的EBSD图

图4a2~d2表明,C0、C0.1和C0.4均为FCC单相结构,而C1和C2.8样品为FCC+HCP双相结构

在C0、C0.1和C0.4样品中出现大量的(60°<111>)退火孪晶(图4a3~c3)

C1样品中的退火孪晶急剧减少(图4d3);胞状晶内部出现大量的小角度晶界,表明胞状晶内存在较高的应力

C2.8样品中的退火孪晶基本消失,在胞状晶区也能出现大量的小角度晶界(图4e3)

图4

图4均匀态(VCoNi)100-x C x (x=0, 0.1, 0.4, 1和2.8)的EBSD图

Fig.4EBSD of as-homogenized samples (VCoNi)100-x C x (x=0, 0.1, 0.4, 1 and 2.8) (a~e). inverse pole figure (a1~e1); phase maps (a2~e2) and grains boundary maps(a3~e3)

图5给出了均匀态(VCoNi)100-x C x (x=0,0.1,0.4,1和2.8)的取向分布函数截面图,ODF图以φ2=45°、65°和90°截面图显示,其主要织构成分的体积分数在图6中给出

图5a表明,C0样品含有G/B织构组分(9.24%)和Cu织构组分(10.4%)

图5b表明,C0.1样品中的Brass织构的体积分数明显增大(12.7%)、S织构组分稍有增加(7.88%),而其他组分有所减少

图5c表明,C0.4样品中的S织构大幅增强(13.7%),表现出以Brass和G/B织构组分为主的α取向线特征

图5a~c表明,随着C含量的提高,均匀态样品的织构逐渐向α取向线上聚集(即取向线φ1=0°→90°、φ=45°、φ2=90°),但是强度降低(从6.6 mrd降至2.36 mrd)

图5d~e表明,C1和C2.4样品中未出现典型织构类型

图5

图5均匀态(VCoNi)100-x C x (x=0, 0.1, 0.4, 1和2.8)的ODF图(φ2=45°、65°和90°截面)

Fig.5φ2=45°, 65° and 90° sections of ODF for the as-homogenized samples (a) C0; (b) C0.1; (c) C0.4; (d) C1; (e) C2.8

图6

图6均匀态样品中主要织构组分的体积分数随C含量的变化

Fig.6Volume fractions of main texture components in as-homogenized samples with different C contents

图7给出了再结晶态(VCoNi)100-x C x (x=0,0.1和0.4)样品的SEM形貌(C1和C2.8样品因在热压缩过程中提前断裂,不适合制备再结晶样品)

可以看出,再结晶态样品的晶粒形态均呈等轴状,出现大量的板条组织,其平均晶粒尺寸分别约为5.02 μm(图7a)、4.79 μm(图7b)和4.22 μm(图7c)

随着C含量的提高,显著析出了第二相颗粒

图8给出了再结晶态(VCoNi)100-x C x (x=0,0.1和0.4)样品的EBSD图

图8a2~c2(相图)表明,再结晶态样品均呈FCC单相结构,图中的白色区域为第二相的位置

在图8a3~c3(晶界图)中可观察到高比例的退火孪晶(60°<111>),其比例分别为46.3%、59.1%和55.2%

图7

图7再结晶态(VCoNi)100-x C x (x=0, 0.1和0.4)的SEM照片

Fig.7SEM images of microstructure for the as-recrystallized samples (a) C0; (b) C0.1;(c) C0.4

图8

图8再结晶态(VCoNi)100-x C x (x=0, 0.1和0.4)的EBSD图

Fig.8EBSD maps of as-recrystallized (VCoNi)100-x C x (x=0, 0.1 and 0.4) samples in (a~c), respectively (a1~c1) IPF maps; (a2~c2) phase maps; (a3~c3) GB maps

图9给出了(VCoNi)100-x C x (x=0,0.1和0.4)再结晶样品在φ2=45°、60°和90°截面取向分布函数图

φ2=90°图显示,三种样品的织构均在α线上聚集,织构最强点均在α取向线上

φ2=45°图显示,样品中出现明显Cu织构组分

根据φ2=65°织构图,可得到样品均存在一定量的S织构

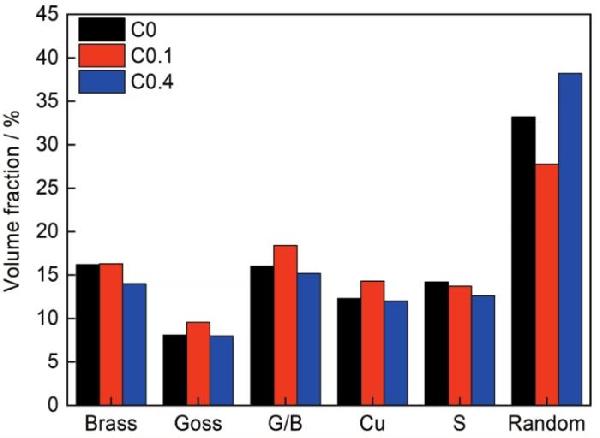

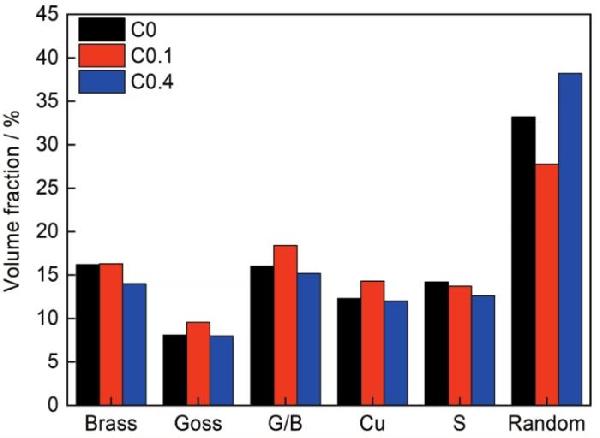

图10统计了再结晶态样品主要织构组分的体积分数

结果表明,C0样品中的Brass和G/B为体积分数最高的织构组分,其比例分别为16.2%和16%,S织构组分占14.2%

C0.1样品的G/B和Cu织构组分增强,其体积分数分别为18.4%和14.3%

C0.4样品的α取向线上各组分的体积分数都减小,Cu和S织构组分减小而随机织构增强

图9

图9再结晶态(VCoNi)100-x C x (x=0, 0.1和0.4)的ODF图(φ2=45°、65°和90°截面)

Fig.9φ2=45°, 65° and 90° sections of the ODFs (determined by EBSD) of as-recrystallized C0 sample in (a), C0.1 sample in (b), C0.4 sample in (c)

图10

图10再结晶态样品中主要织构组分的体积分数随C含量的变化

Fig.10Volume fractions of main texture components in as-recrystallized samples with different C contents

图11a给出了再结晶态(VCoNi)100-x C x (x=0,0.1和0.4)样品的室温拉伸曲线,表1列出了屈服强度、抗拉强度和延伸率的具体数值,其中C0.1表现出最优的强韧化性能

图11b表明,样品的拉伸曲线均呈现出典型的三段式加工硬化率

第一阶段,加工硬化率下降,塑性变形由位错滑移主导,动态回复引起的位错塞积速率降低,使加工硬化率减小

此时,C0.1和C0.4样品的加工硬化率略高于C0样品

第二阶段,加工硬化率的下降减缓,三种样品呈现出近似的加工硬化率

第三阶段的加工硬化率曲线均随着真应变的增加而急剧下降,直至断裂

图11

图11再结晶态(VCoNi)100-x C x (x=0, 0.1和0.4)的室温拉伸曲线和断口形貌

Fig.11representative tensile engineering stress-strain curves(a); corresponding strain-hardening rate curves (b); fracture surfaces of as-recrystallized C0, C0.1 and C0.4 samples are shown in (c), (d) and (e)

Table 1

表1

表1(VCoNi)100-x C x 中熵合金的屈服强度、抗拉强度以及延伸率

Table 1Yield strength, ultimate tensile strength and elongation of (VCoNi)100-x C x medium entropy alloy

|

|

Yield Strength

/ MPa

|

Ultimate tensile strength

/ MPa

|

Elongation

/ %

|

|

C0

|

528.30

|

1003.29

|

54.23

|

|

C0.1

|

744.62

|

1193.86

|

39.25

|

|

C0.4

|

686.68

|

1130.22

|

39.37

|

图11c1~f1表明,样品均出现明显的缩颈现象且断口形貌均由分布均匀的韧窝组成,为典型的韧性断裂

图11c表明,C0样品的断口有大量的韧窝,其尺寸大且比较深,表明其具有较好的塑性

而含C样品断口的形貌发生了变化:第一,韧窝的深度和尺寸减小(图11c3~e3);第二,断口的部分区域出现了解理小平面(图11d2~e2,黑色箭头);第三,在C0.1样品的韧窝中心可观察到第二相颗粒(图11d3~e3,红色区域)

由此可见,样品断口形貌的特征与其拉伸力学性能匹配,韧窝深度和尺寸的减小以及解理小平面的出现,都意味着塑性的降低

图12给出了再结晶态(VCoNi)100-x C x (x=0,0.1和0.4)样品在干摩擦条件下的摩擦磨损性能和磨痕形貌

图12a(摩擦系数曲线)表明,所有曲线都显示出类似的两阶段(磨合和稳态)摩擦行为

在第一次磨合阶段,由于磨损表面的损伤和接触面积的增大,摩擦曲线很快到达最高点然后迅速下降,接着摩擦系数随着滑动时间的增加而逐渐增大

图12a显示出C0.1样品摩擦曲线很快进入平直阶段(约2.8 min),表明该样品很快进入稳定摩擦阶段,而C0和C0.4样品则需要较长的磨合期(分别约3.7和4.5 min)才能进入稳定摩擦阶段

图12b表明,添加C原子的VCoNi合金,其摩擦系数的变化趋势没有明显的差异,但是其平均摩擦系数增大(稳定期)而磨损率降低

三维磨损表面的形貌(图12d1~f1)表明,C0.1和C0.4样品的磨痕宽度比C0样品的小

从磨痕中心区域的截面二维轮廓图(图12c)可见,磨痕宽度分别为1.006 mm(C0样品)、0.986 mm(C0.1样品)和0.911 mm(C0.4样品),磨痕平均深度分别为6.482 μm(C0样品)、5.482 μm(C0.1样品)和5.587 μm(C0.4样品)

这表明,添加C原子使VCoNi中熵合金的耐磨性能提高

图12

图12再结晶态(VCoNi)100-x C x (x=0, 0.1和0.4)的摩擦磨损性能和磨痕形貌

Fig.12Real time friction coefficient (a); average friction coefficient and wear rate (b); wear scar profile (c); wear scar morphology of as-recrystallized C0 sample (d), C0.1 sample (e) and C0.4 sample (f)

图12d~f(磨痕形貌)表明,三种再结晶态样品的磨损表面均由犁沟和磨屑组成

图12d2~d3表明,C0样品的磨痕分为黑色氧化区和灰色未氧化区,磨痕表面有明显的与滑动方向相同的犁沟型划痕以及在部分区域出现一些黑色大块氧化膜、细小的麻点以及小型的鱼鳞片状碎片

这表明,基体样品的磨损机制属于氧化磨损、磨粒磨损和粘着磨损

图12e2表明,C0.1样品表面的犁沟型划痕变浅,磨粒磨损的作用减弱;而磨痕表面黑色区域增大(图12e3),样品磨损产生的氧化增加,鱼鳞片状碎片明显增多,表明氧化磨损和粘着磨损的作用加强

由此可见,C0.1样品的磨损机制为磨粒磨损、氧化磨损和粘着磨损

图12f表明,C0.4样品的磨痕表面形貌与C0.1样品基本相同,但是黑色区域增大和鱼鳞片状碎片明显增加(图12f3),表明C0.4样品的磨损机制仍为磨粒磨损、氧化磨损和粘着磨损

3 讨论

添加不同含量的C影响VCoNi合金的微观组织

第一,C0、C0.1和C0.4均匀态样品中(图2a~c)的晶粒形态为等轴晶组织和板条状的退火孪晶;而C1均匀态样品中(图2d)的晶粒形态为胞状晶,C2.8样品中(图2e)的晶粒形态为胞状晶

生成胞状晶的原因是,添加过多的C原子导致HCP相的生成(图1)

第二,随着C含量的提高,V和C原子明显富集(图3)

其原因是,在快速冷却过程中C和V极强的亲和力[29]使其极易生成钒碳化合物析出相

同时,随着C含量的提高,钒碳化合物增加

第三,含C再结晶态样品的晶粒发生了细化,主要与第二相有关

在退火过程中第二相对晶界的钉扎抑制了再结晶晶粒的长大[30]

含C再结晶样品的屈服强度和抗拉强度均提高(图11a,b),而塑性略有降低

其主要原因是:第一,在VCoNi固溶体系中的C提供了间隙强化

第二,部分在晶界处析出的第二相使晶界界面能降低,降低了晶粒长大驱动力[31],导致晶粒细化(图8a1~c1)而产生了细晶强化

第三,晶界处C原子的偏聚引起晶界内聚力增大,沿晶断裂分数的减小有助于稳定韧性[32],从而使含C样品断口的形貌仍旧以韧窝形貌为主(图11c~e)

因此,C0.1和C0.4样品的屈服强度和抗拉强度显著提高

但是,C含量为0.4的样品其屈服强度和抗拉强度呈下降趋势,表明再结晶态C0.1样品中第二相的形态和尺寸均已达到最佳,从而使样品具有优异的强韧化综合力学性能

添加C原子样品的摩擦磨损能力更高,可归因于两个方面的原因

第一,含C样品在晶界处析出的硬质钒碳化合物,提高了样品的硬度从而增强了粘着磨损行为

第二,频繁的氧化磨损使含C样品表面在高速摩擦过程中迅速氧化,生成的氧化物黏着在摩擦表面

时间越长则氧化层越厚,产生的润滑作用降低了样品的磨损率,从而使样品的耐磨性能提高

4 结论

(1) x=0~1的(VCoNi)100-x C x 熵合金均匀态样品中的晶粒形态为等轴晶,且出现退火孪晶,随着C含量的提高,晶粒尺寸减小,呈颗粒状的第二相的含量提高;在x≥1的样品中出现了粗大的胞晶,第二相呈现多形态特征,退火孪晶减少

再结晶态样品中晶粒的形态均呈等轴晶状,随着C含量的提高,晶粒尺寸减小,第二相的含量提高

(2) 均匀态C0样品以G/B和Cu织构为主,C0.1样品Brass织构的体积分数明显增大,C0.4样品具有以Brass和G/B织构组分为主的α取向线特征,在C1和C2.4样品中未出现典型织构类型

再结晶态样品均表现出在α线上聚集,且织构最强点均在α取向线上

(3) C0.1再结晶态样品具有最优的强韧化性能,因为适量的C原子使第二相的形态和尺寸均达到最佳,实现了细晶强化、间隙强化和第二相强化

(4) 含C原子的再结晶样品的摩擦磨损性能提高,因为C原子生成的钒碳化合物增强了粘着磨损和氧化磨损,减弱了磨粒磨损,生成的氧化层减少了样品的磨损

参考文献

View Option 原文顺序文献年度倒序文中引用次数倒序被引期刊影响因子

[1]

Tsai M H, Yeh J W.

High-entropy alloys: a critical review

[J]. Mater. Res. Lett., 2014, 2(3): 107

DOIURL [本文引用: 2]

[2]

Miracle D B, Senkov O N.

A critical review of high entropy alloys and related concepts

[J]. Acta Mater., 2017, 122: 448

DOIURL [本文引用: 1]

[3]

Yeh J W, Chen S K, Lin S J, et al.

Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes

[J]. Adv. Eng. Mater., 2004, 6(5): 299

DOIURL

[4]

Cantor B, Chang I T H, Knight P, et al.

Microstructural development in equiatomic multicomponent alloys

[J]. Mat. Sci. Eng. A-Struct., 2004, 375: 213

[本文引用: 1]

[5]

Zhang Y, Zuo T T, Tang Z, et al.

Microstructures and properties of high-entropy alloys

[J]. Prog. Mater. Sci., 2014, 61: 1

DOIURL [本文引用: 1]

[6]

Lin Q, Liu J, An X, et al.

Cryogenic-deformation-induced phase transformation in an FeCoCrNi high-entropy alloy

[J], Mater. Res. Lett., 2018(6): 236

[本文引用: 1]

[7]

Yang T, Guo W, Poplawsky J D, et al.

Structural damage and phase stability of Al0.3CoCrFeNi high entropy alloy under high temperature ion irradiation

[J], Acta Mater., 2020(188): 1

[8]

Schneider M, George E P, Manescau T J, et al.

Analysis of strengthening due to grain boundaries and annealing twin boundaries in the CrCoNi medium-entropy alloy

[J]. Int. J. Plast., 2020(124): 155

[9]

Nam S, Kim C, Kim Y M.

Recent studies of the lasercladding of high entropy alloys

[J]. J. Weld. & Join., 2017, 35(4): 58

[10]

Agustianingrum M P, Park N, Yoshida S, et al.

Effect of aluminum addition on solid solution strengthening in CoCrNi medium-entropy alloy

[J]. J. Alloy Compd., 2019(781): 866

[11]

Senkov O N, Wilks G B, Scott J M, et al.

Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys

[J]. Intermetallics, 2011, 19(5): 698

DOIURL

[12]

Lu C, Niu L, Chen N, et al.

Enhancing radiation tolerance by controlling defect mobility and migration pathways in multicomponent single-phase alloys

[J]. Nat. Commun., 2016, 7(1): 13564

DOI " />

Interactions of impurity interstitial atoms with dislocations may play an important role in strengthening of structural materials as well as in other phenomena like hydrogen embrittlement. Impurity interstitial atoms occupy octahedral (typical for carbon) or tetrahedral (typical for hydrogen) sites in bcc metals, both showing solely tetragonal symmetry of three types distinguished by orientation with respect to the main crystallographic (1, 2, 3) directions. Placing an atom at one of such sites one of the three types of local multiaxial eigenstrain states is provoked. This eigenstrain state interacts with the stress field of the dislocation, and the corresponding interaction term provides a mechanical part of the generalized chemical potential of the interstitial component. For a proper description of the distribution of the interstitial component in the stressed lattice three site fractions X-1, X-2 and X-3, corresponding to the types of sites, are necessary. Interstitials like hydrogen and carbon are mobile even at room temperature and diffuse spontaneously to places with the lowest interaction energy. As the individual types of interstitial sites are interconnected by fast diffusion paths, one can assume local equilibrium among atoms occupying the three types of interstitial sites. This fact is expressed by a unique value of their generalized chemical potential. The gradient of this potential drives diffusion of interstitial atoms. At any time the atoms redistribute locally to the three types of sites according to the condition of local equilibrium. Thus, generally in the stressed bcc lattice the three site fractions X-1, X-2 and X-3 have different values and provoke a multiaxial eigenstrain state resulting in an eigenstress state. Hence, the stress field of the dislocation is superposed by the eigenstress state. This may cause a significant relaxation (i.e. reduction) of the total stress state depending on the amount of the interstitial atoms in the system and their diffusion kinetics. Very recently, the individual diffusion paths of interstitial atoms occupying octahedral or tetrahedral positions in a stressed bcc lattice have been identified. The respective model predicts a significant anisotropy of diffusion caused by the differences in local values of X-1, X-2 and X-3 in addition to the standard elastodiffusion due to deformation of the lattice. This leads to a significant modification of the standard diffusion equation, because the introduced "diffusion occupancy factors" are directly dependent on the values of X-1, X-2 and X-3. Assuming a straight dislocation (with its dislocation line coinciding with the z-coordinate axis and the slip plane as the x-z-plane of the local coordinate system) and its interaction with the interstitial component, it is advantageous to evaluate the eigenstrain tensor in the local coordinate system (x, y, z) and solve the problem in that system. Then the space around the dislocation can be divided into cylindrical representative volume elements with axes parallel to z-axis and small cross-sections in x- and y- directions. In each of the representative volume elements spatially constant values of Xi, X-2 and X-3 and of the eigenstrain tensor are assumed. As one can calculate the eigenstress state inside and outside of each cylindrical representative volume element, embedded in an eigenstrain-free infinite matrix, the total stress state is then given by linear superposition of the eigenstress states of all representative volume elements and the stress state induced by the dislocation. The goal of the proposed review paper is to comprise a collection of the knowledge of the last seven decades dealing with the following topics: stress fields induced by edge and screw dislocation; a presentation of the most recent solution technique and discussion of previous solutions; eigenstrains of carbon and hydrogen atoms placed in octahedral and tetrahedral sites; a selection of the values of reliable sources; assembling of the interstitial atoms, acting as inclusions with a misfit eigenstrain state, in cylindrical representative volume elements; eigenstrain states in cylindrical representative volume elements due to occupancy of interstitial atoms described by X-1, X-2 and X-3; eigenstress fields generated by eigenstrains in cylindrical representative volume elements; formulation of the generalized chemical potential of interstitial atoms in the stressed bcc lattice; anisotropic diffusion equations for interstitials in a stressed bcc lattice, accounting for elastodiffusion and the effect of occupancy of different types of interstitial sites. A collection of equations provides a basis for acquiring a complex model of kinetics of interactions of interstitial atoms with (especially prioritizing) dislocations in the bcc lattice. This represents the "research part" of the review paper. Thus the paper focuses on kinetics of interactions of interstitials occupying tetrahedral and octahedral positions with edge and screw dislocations. As results of simulations the kinetics of distribution of the site fractions X-1, X-2 and X-3 around the dislocation as well as the relaxation (i.e. reduction) of the dislocation stress due to eigenstress are provided.

[15]

Moon J, Jang M J, Bae J W, et al.

Mechanical behavior and solid solution strengthening model for face-centered cubic single crystalline and polycrystalline high-entropy alloys

[J]. Intermetallics, 2018, 98: 89

DOIURL

[16]

Sohn S S, Da Silva A K, Ikeda Y, et al.

Ultrastrong medium-entropy single-phase alloys designed via severe lattice distortion

[J]. Adv. Mater., 2019, 31(8): 8

[本文引用: 3]

[17]

Sohn S S, Kim D G, Jo Y H, et al.

High-rate superplasticity in an equiatomic medium-entropy VCoNi alloy enabled through dynamic recrystallization of a duplex microstructure of ordered phases

[J]. Acta Mater., 2020, 194: 106

DOIURL [本文引用: 1]

[18]

ChenY, Tu J, Zhang Y B, et al.

Effect of deformation and annealing process on microstructural evolution of Fe47Mn30Co10Cr10B3 high entropy alloy

[J]. Chin. J. Mater. Res., 2021, 35(2): 143

[本文引用: 1]

陈 扬, 涂 坚, 张琰斌 等.

形变和退火对Fe47Mn30Co10Cr10B3间隙高熵合金微观组织结构演变的影响

[J]. 材料研究学报, 2021, 35(2): 143

[本文引用: 1]

[19]

Yang M X, Yan D S, Yuan F P, et al.

Dynamically reinforced heterogeneous grain structure prolongs ductility in a medium-entropy alloy with gigapascal yield strength

[J]. Proc. Natl. Acad. Sci. U S A, 2018, 115(28): 7224

DOIURL [本文引用: 1] " />

Interstitial solid strengthening is an effective strategy to harden metallic materials, however, it usually deteriorates the ductility. Here, we report that addition of carbon into the medium-entropy NiCoCr alloy successfully enhances the strength at no expense of ductility. It was found that up to 0.75 at.% carbon was completely solid-solutionized in (NiCoCr)(100-x)C-x (x = 0, 0.10, 0.25, 0.50 and 0.75 at.%) without formation of any carbides. With the increase of carbon content from 0 to 0.75 at.%, the yield and fracture strength were increased from 242 to 347 MPa to 727 and 862 MPa, respectively, whilst the ductility kept as high as about 75%. It is noteworthy that the integral of the stress over strain for the alloy with 0.75 at.% carbon reaches a value of 59 GPa %, surmounting the level of many reported multi-principal elements alloys. Our analysis indicates that carbon addition increases stacking fault energy, thus delaying occurrence of twinning and decreasing the thickness of twin lamellas. At the early deformation stage, carbon decreases the stress localization and stimulates dislocation multiplication. After occurrence of deformation twinning, finer twinning structure in the alloys added with carbon not only can obstacle and trigger more dislocations, but also transfer plastic deformation more efficiently, thus promoting the twinning process, postponing the plastic instability and eventually giving rise to a more pronounced work-hardening. Our results not only have important implications for understanding the solid solution strengthening mechanism in medium-entropy alloys, but also shed lights on developing advanced metallic alloys with a unique combination of strength and ductility.

[21]

Stepanov N D, Shaysultanov D G, Chernichenko R S, et al.

Effect of thermomechanical processing on microstructure and mechanical properties of the carbon-containing CoCrFeNiMn high entropy alloy

[J]. J. Alloy Compd., 2017, 693: 394

DOIURL [本文引用: 1]

[22]

Wang Z W, Lu W J, Raabe D, et al.

On the mechanism of extraordinary strain hardening in an interstitial high-entropy alloy under cryogenic conditions

[J]. J. Alloy Compd., 2019, 781: 734

DOIURL [本文引用: 1]

[23]

Saha J, Bhattacharjee P P.

Influences of Thermomechanical Processing by Severe Cold and Warm Rolling on the Microstructure, Texture, and Mechanical Properties of an Equiatomic CoCrNi Medium-Entropy Alloy

[J]. J. Mater. Eng. Perform., 2021, 30(12): 8956

DOI [本文引用: 1]

[24]

Bhattacharjee P P, Sathiaraj G D, Zaid M, et al.

Microstructure and texture evolution during annealing of equiatomic CoCrFeMnNi high-entropy alloy

[J]. J. Alloy Compd., 2014, 587: 544

DOIURL [本文引用: 1]

[25]

Xiao J K, Tan H, Chen J, et al.

Effect of carbon content on microstructure, hardness and wear resistance of CoCrFeMnNiCx high-entropy alloys

[J]. J. Alloy Compd., 2020, 847: 156533

DOIURL [本文引用: 1]

[26]

Liu J Z, Liu H X, Di Y N, et al.

Effects of carbon content on friction and wear behavior and corrosion resistance of laser cladding CoCrFeMnNiC x high entropy alloy coatings

[J]. China Surface Engineering, 2020, 33(6): 118

[本文引用: 1]

刘径舟, 刘洪喜, 邸英南 等.

碳含量对激光熔覆CoCrFeMnNiC x 熵合金涂层摩擦磨损和耐蚀性能的影响

[J]. 中国表面工程, 2020, 33(6): 118

[本文引用: 1]

[27]

Deng L, Bai C Y, Jiang Z T, et al.

Effect of B4C particles addition on microstructure and mechanical properties of Fe50Mn30Co10Cr10 high-entropy alloy

[J]. Mat. Sci. Eng. A, 2021, 822: 141642

DOIURL [本文引用: 1]

[28]

Andersson J O, Helander T, Hoglund L H, et al.

THERMO-CALC and DICTRA, computational tools for materials science

[J]. Calphad, 2002, 26(2): 273

DOIURL [本文引用: 1]

[29]

Sathiaraj G D, Bhattacharjee P P.

Effect of cold-rolling strain on the evolution of annealing texture of equiatomic CoCrFeMnNi high entropy alloy

[J]. Mater. Charact., 2015, 109: 189

DOIURL [本文引用: 1]

[30]

Li Z Q, Wang J S, Huang H B.

Influences of grain/particle interfacial energies on second-phase particle pinning grain coarsening of polycrystalline

[J]. J. Alloy Compd., 2020, 818: 10

[本文引用: 1]

[31]

Seol J B, Bae J W, Li Z M, et al.

Boron doped ultrastrong and ductile high-entropy alloys

[J]. Acta Mater, 2018, 151: 366

DOIURL [本文引用: 1]

[32]

Suzuki S, Abiko K, Kimura H.

Chemical state of phosphorus segregated at grain boundaries in iron

[J]. Transactions of the Iron and Steel Institute of Japan, 1983, 23(9): 746

DOIURL [本文引用: 1]

High-entropy alloys: a critical review

2

2014

声明:

“C含量对VCoNi中熵合金微观组织和性能的影响” 该技术专利(论文)所有权利归属于技术(论文)所有人。仅供学习研究,如用于商业用途,请联系该技术所有人。

我是此专利(论文)的发明人(作者)

647

编辑:中冶有色技术网

来源:幸定琴,涂坚,罗森,周志明

647

编辑:中冶有色技术网

来源:幸定琴,涂坚,罗森,周志明

举报 0

举报 0

收藏 0

收藏 0

反对 0

反对 0

点赞 0

点赞 0