研制清洁、安全和高效的核能系统(如超高温反应堆,快反应堆等)是能源领域的热点问题,但是传统核结构材料在新型堆恶劣的高温、强辐照、强腐蚀服役环境中产生辐照硬化、肿胀、氢脆和辐照应力腐蚀[1,2]

由四种及四种以上元素组成的高熵合金(HEAs),具有独特的多主元效应和优异的力学性能

研究表明,HEAs独特的微观结构使其具有优异的抗辐照性能[3,4]

同时,调控成分和结构可使HEAs满足特定应用场景的性能要求[5,6]

目前,对HEAs的研究主要聚焦于面心立方(FCC)及体心立方(BCC)结构HEAs

与具有良好延展性的FCC型HEAs相比[6],BCC型HEAs多由Ti、Nb、Hf、Mo、Zr、V、Ta和W等难熔元素组成,结构的影响使其室温塑性较差[9~11],但是优异的高温力学性能可满足核结构材料的严苛要求[12~15]

在难熔高熵合金(RHEAs)中添加Nb、Mo、Zr等元素,可使其基体形成稳定的BCC结构[16,17]

一些非难熔元素(Al、B、Si和Ni等)的添加,可进一步提高其综合性能[18]

在HEAs中添加Al元素可生成复杂氧化物,使其抗高温氧化能力提高[19~21]

可燃毒物B元素具有高中子吸收截面(750 barns),将其引入可在时间上补偿初期堆芯过剩反应并在空间上平衡功率分布,为RHEAs作为长循环堆芯燃料包壳或弥散燃料的惰性基体提供了可能

Kang等[22]在Al0.1CrNbVMo RHEA中掺入B,使其力学性能显著提高

评估核应用前景的关键因素,包括对合金辐照损伤行为和机理的研究

本文在AlNbMoZr中添加硼(B)元素制备一种具有可燃毒物特性的新型BCC结构Al5-Nb40-Mo40-Zr15-B0.1 RHEAs(简称AlNbMoZrB),研究其Kr离子辐照损伤行为

1 实验方法

使用水冷铜坩埚电弧熔炼法(在高纯氩气保护下)制备难熔高熵合金Al5-Nb40-Mo40-Zr15-B0.1(原子分数,简称AlNbMoZrB)铸锭

原料中的Nb、Mo、Al、Zr等金属的纯度高于99.9%(质量分数),B元素以AlB3的形式添加

熔炼合金铸锭前,先熔炼一遍Ti锭以吸收电弧炉内的残余氧气

合金锭至少翻转熔炼6次,每次熔炼时长不少于5 min,以确保成分均匀

用于测试和分析的所有样品,均使用线切自铸锭的中间部分割取

实验前用400#至5000#砂纸逐级打磨观察面,然后用粒径50 nm的SiO2抛光液进行机械抛光至表面镜面光滑

使用电子万能试验机完成室温压缩试验

压缩试样是直径为4 mm、长度为6 mm的圆柱,压缩应变速率设置为1×10-3 s-1,重复三次试验以保证结果的准确性,根据所得的数据画出试样的压缩应力应变曲线

测定XRD谱以分析合金相结构及晶格畸变,用Cu-Kα靶材产生的X射线为射线源,扫描速度为6 (°)/min,2θ范围为20°~100°

用SEM的背散射电子模式(FEG-SEM, Zeiss Sigma HD)及能谱仪(EDS)分析合金的相结构及元素分布

使用LC-4离子注入器分别在室温和300℃对抛光的AlNbMoZrB样品进行Kr离子辐照,注入能量为4 MeV,最终注入量达到6×1015 ions/cm2

使用聚焦离子束(FIB)技术沿样品辐照截面制备透射电子显微镜(TEM)样品,其厚度约为50 nm,用TEM及配备的EDS探头观察并分析辐照诱导相变、位错环、Kr泡等缺陷的演化

将样品按相组成和辐照情况分区分别进行TEM及EDS表征

在不同温度条件下,以研究经Kr离子辐照后AlNbMoZrB合金的相组成和辐照诱导缺陷的演化

2 结果和讨论2.1 AlNbMoZrB合金的力学性能和组成

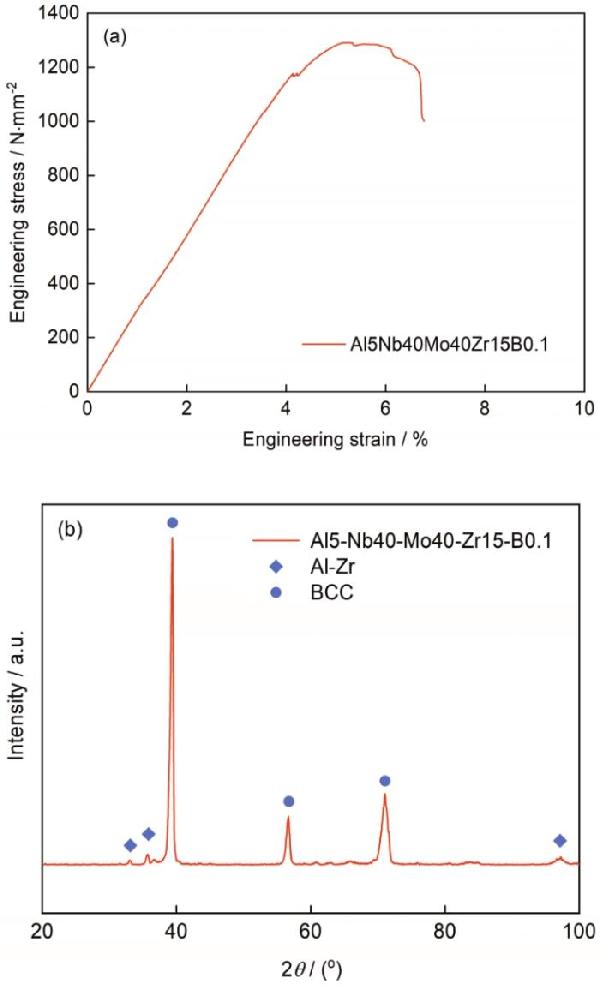

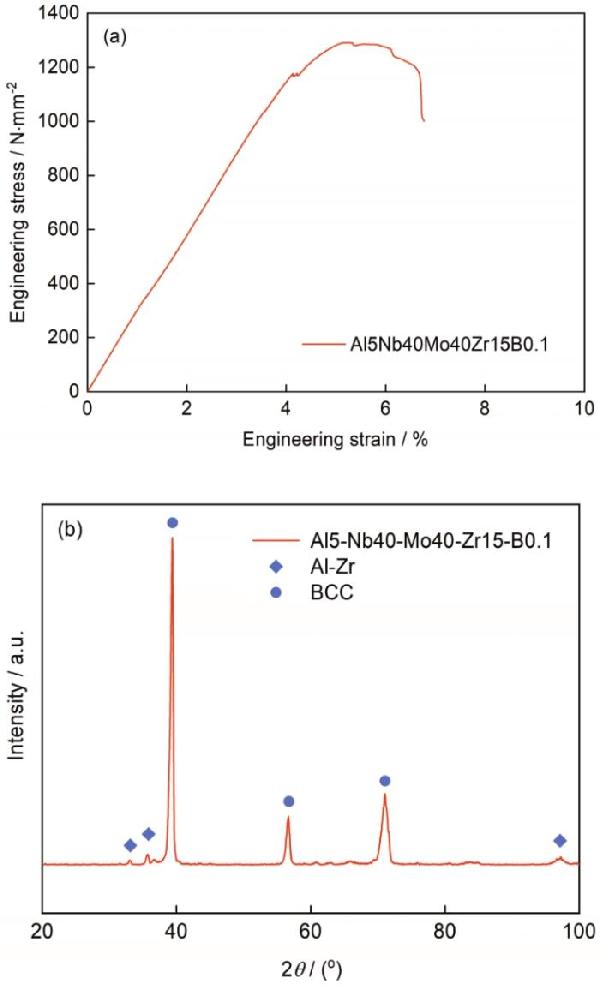

对铸态AlNbMoZrB合金进行室温压缩测试,结果如图1a所示

可以看出,试样的屈服强度约为1180 MPa,压缩强度约为1274 MPa,塑性约为4.8%

AlNbMoZrB合金的XRD谱如图1b所示,根据特征衍射峰的位置可判断合金由BCC结构的基体相和FCC结构的Al-Zr相组成

图1

图1铸态AlNbMoZrB合金的压缩应力-应变曲线和XRD谱

Fig.1Compressive stress-strain curves (a) and XRD spectrum (b) of as-cast AlNbMoZrB alloy

Table 1

表1

表1铸态合金的室温压缩屈服强度、断裂强度和压缩率

Table 1Compression yield strength, fracture strength and compression ratio of as-cast and solid-solution alloys at room temperature

|

Alloy

|

σc0.2

/MPa

|

σp

/MPa

|

εp

/%

|

|

Al5Nb40Mo40Zr15B0.1-cast

|

1180

|

1274

|

4.8

|

根据结构或能量和经验参数可预测并分析高熵合金的相组成及其形成过程,其中价电子浓度(VEC)及混合焓(Hmix)

VEC=∑i=1NxiVECi

ΔHmix=∑i=1,i≠jn4ΔHijmixcicj

可用于判断高熵合金固溶体相类型

式中xi 为第i个元素的原子分数,VEC i 为第i个元素的VEC,ΔHijmix为第i和第j分量之间的混合焓,ci 、cj 分别为第i、j元素的原子分数

VEC低于6.87时倾向于形成BCC单相结构,VEC高于8时倾向于形成FCC单相结构,;VEC为6.87~8时易形成FCC+BCC双相结构[23],-11.6 kJ/mol<ΔHmix<3.2 kJ/mol时倾向于形成单相固溶体[24]

计算结果表明,AlNbMoZrB合金的VEC为5.15,但是合金中却含有FCC结构Al-Zr相

这与Al、Zr元素之间的负混合焓(-51.5 kJ/mol)相关,二者间极小的混合焓值使合金的ΔHijmix降低到-15.3 kJ/mol,最终导致在含有Al、Zr元素的高熵合金中易于形成Al-Zr相

这表明,热力学条件主导AlNbMoZrB合金相的形成

值得注意的是,B元素与Al、Nb、Mo、Zr元素的二元合金混合焓分别为0、-54 kJ/mol、-34 kJ/mol、-71 kJ/mol[25],但是在XRD谱中并没有出现明显的硼化物衍射峰

据此可以推测,B原子可能作为间隙原子溶于合金基体,从而引发晶格畸变并使合金的晶格常数增大

2.2 AlNbMoZrB合金的SEM形貌

图2给出了铸态AlNbMoZrB合金的SEM形貌及对应的EDS和XRD谱

可以看出,AlNbMoZrB合金具有典型的枝晶结构,可分为白色衬度的枝晶区和灰色衬度的枝晶间区(图2a和2b)

同时,在枝晶间区内还出现了少量黑色衬度的相组织

图2c中标注的点A、B、C分别对应白、灰、黑三种衬度的相组织,其EDS结果列于表2(由于B元素属于轻原子且名义含量仅为0.1%(原子分数),测得结果存在误差,因此没有标注B元素的含量)

由EDS结果可知,在枝晶区(点A)Nb、Mo和B元素富集,枝晶间区Al和Zr元素富集,且黑色枝晶间区(点C)Zr元素的浓度比灰色枝晶间区(点B)的高

结合XRD谱的表征结果可知,白色枝晶区即为BCC结构固溶体基体相,灰色枝晶间区和黑色枝晶间区分别为FCC结构Al-Zr相和HCP结构α-Zr相

图2

图2铸态AlNbMoZrB合金的背散射图、EDS面和点扫描图

Fig.2Backscatter diagram, EDS mapping and point results of as-cast AlNbMoZrB alloy (a) (b) corresponding Backscatter images of as-cast AlNbMoZrB alloy, and (c) corresponding Backscatter, EDS mapping and point results image of typical dendritic region of as-cast AlNbMoZrB alloy

Table 2

表2

表2铸态AlNbMoZrB合金的EDS点扫描结果

Table 2EDS point results of as-cast AlNbMoZrB alloy (atomic fraction, %)

|

Points

|

Al

|

Nb

|

Mo

|

Zr

|

Nominal composition

A (white dendrite rigon)

B (gray interdendritic rigon)

C (black interdendritic rigon)

|

5

2.06

15.65

14.67

|

40

46.89

19.97

19.43

|

40

42.31

27.88

6.62

|

15

8.74

36.50

59.28

|

为了更好地观察B元素在合金中的分布,对AlNbMoZrB铸态合金进行了低电压模式扫描,图3给出的EDS面扫描结果与高电压模式下的结果一致

Al、Zr元素主要分布在枝晶间区,而Nb、Mo、B元素主要分布在枝晶区,且没有生成硼化物

结合XRD谱的分析结果进一步证明,B元素以间隙原子的形式固溶在合金基体中

图3

图3铸态AlNbMoZrB合金低电压下的背散射图和面扫图

Fig.3Backscatter diagram, EDS mapping and point results of as-cast AlNbMoZrB alloy under low-voltage

2.3 AlNbMoZrB合金Kr离子辐照损伤行为

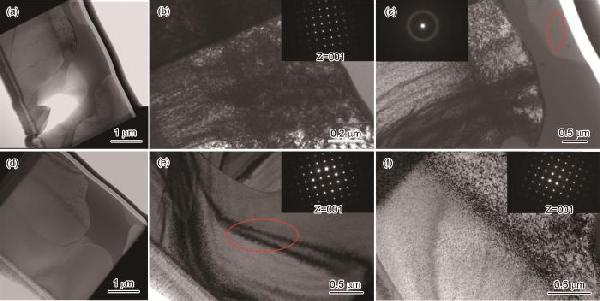

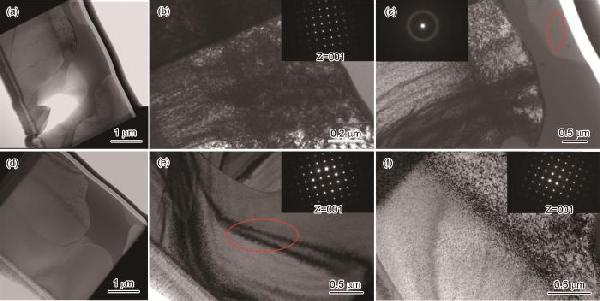

图4给出了在室温条件辐照样品的TEM形貌

根据图4可判断在室温和300℃辐照影响区的深度分别约为1200 nm及1300 nm

图4a~c对应室温辐照样品的TEM图像,其中a1~a3位置在辐照影响区内,a4~a6位置未受辐照影响,各点对应的EDS结果列于表3

其中,a3及a5区域Nb、Mo元素富集,a3区域所对应的TEM图像和选区衍射谱(SAED)如图4b所示,SAED图像(沿[001]区轴)证明该位置对应BCC结构,因此a5、a3区域分别为辐照前后AlNbMoZrB合金枝晶区BCC结构基体相,枝晶区元素成分及晶体结构未发生变化

此外结合此前的SEM及XRD结果可知,a2、a6位置Al、Zr元素富集,对应枝晶间区Al-Zr相,而a1位置EDS结果显示其Zr元素含量高达~71.4%,对应枝晶间区α-Zr相

图4c中a1区域的TEM及SAED图像呈现出典型非晶衍射花样特征,证明在室温离子辐照下的AlNbMoZrB合金发生了α-Zr相辐照诱导非晶化转变

这些α-Zr相在高能离子辐照下,由于级联碰撞产生的点缺陷使其有序结构受到破坏,无序化程度的累积最终使其发生非晶化转变[26]

与高温相比,室温辐照条件下点缺陷复合速率较低,系统自由能易于升高,因此非晶化转变的临界辐照剂量降低,更容易发生非晶化转变[27]

图4

图4AlNbMoZrB在4.8×1015/cm2 Kr离子辐照条件下的室温TEM形貌

Fig.4TEM images of AlNbMoZrB under the condition of 4.8×1015/cm2 Kr ion irradiation at room temperature (a) typical regions spot scanning under TEM-EDS mode, (b) corresponding TEM and SAED images of the region 3 in Fig.4a, (c) corresponding TEM and SAED images of the region 1 in Fig.4a (d) (e) (f) TEM image of AlNbMoZrB under 4.8×1015/cm2 Kr ion irradiation at 300℃ (d) typical regions spot scanning under TEM-EDS mode, (e) corresponding TEM and SAED images of the region 4 in Fig.4d, (f) corresponding TEM and SAED images of the region 1 in Fig.4 ddot sweep image (e) BCC crystal image (f) BCC crystal

Table 3

表3

表3AlNbMoZrB合金室温辐照点扫描结果

Table 3EDS point results of as-cast AlNbMoZrB alloy irradiated under room temperature (atomic fraction,%)

|

Points

|

Al

|

Nb

|

Mo

|

Zr

|

a1

a2

a3

a4

a5

a6

|

6.84

9.83

1.97

0.85

1.93

9.17

|

9

21.7

37.67

40.16

39.35

19.21

|

12.76

27.37

45.46

44.07

36.84

27.36

|

71.4

41.09

14.91

14.92

13.15

44.26

|

图4d~f给出了Kr离子在300℃辐照AlNbMoZrB合金样品的TEM形貌和SAED表征结果,对应的EDS结果列于表4

根据辐照影响区范围,d3和d4的位置处于未辐照区,其余位置都受到了辐照

EDS结果表明,在d1~d4的位置Nb、Mo元素富集,为BCC基体相;在d5、d7的位置Al、Zr元素富集,为枝晶间区Al-Zr相;在d6的位置Zr元素的含量高达~74.96%(原子分数),对应α-Zr相

图4e和4f分别对应d4区域和d1区域的TEM形貌和SAED图像,即辐照前后的BCC基体相

对比衍射花样可知,辐照后的合金基体仍保持BCC结构,没有发生相变

Table 4

表4

表4AlNbMoZrB合金在300℃辐照的点扫描结果

Table 4EDS point results of AlNbMoZrB alloy irradiated under 300℃ (atomic fraction, %)

|

Points

|

Al

|

Nb

|

Mo

|

Zr

|

d1

d2

d3

d4

d5

d6

d7

|

2.37

1.88

1.91

2.65

6.61

4.48

4.31

|

42.27

42.64

42.84

45.38

23

11.01

20.61

|

41.46

39.18

38.62

34.76

21.36

9.55

5.25

|

13.89

16.3

16.64

17.21

49.04

74.96

69.83

|

从图5给出的TEM形貌可见,Kr离子辐照后的AlNbMoZrB合金基体中出现大量黑点状的辐照诱导位错环,其分布深度可达1300 nm

统计结果表明,常温Kr离子辐照产生的位错环其体积密度为4.11×1022 m-3,尺寸为12~16 nm;300℃辐照产生的位错环其体积密度约为室温辐照的1/4(即为1.63×1022 m-3),尺寸增大到23~27 nm

这表明,随着辐照温度的升高位错环的数量减少而尺寸增大

其原因是,在高温下可动型位错环的扩散速率提高,使大量位错环复合后尺寸增长

图5

图5室温辐照和300℃辐照AlNbMoZrB合金双束条件下的TEM形貌

Fig.5two-beam conditioned TEM images of AlNbMoZrB at room temperature (a~c) and at 300℃ (d~f)

辐照后体心立方结构金属中的位错环,以<100>型和1/2<111>型两种间隙型位错环为主[28]

为了进一步比较不同类型位错环密度,图5给出了双束条件下的TEM表征结果

选取g0-1-1,g01-1,g00-2为g矢量方向,依据不可见准则g·b=0,结合衍射条件可以判断:经Kr离子辐照后AlNbMoZrB合金中产生的1/2<111>型位错环其体积密度大于<100>型位错环

不同类型位错环的结构特性,显著影响合金的力学性能[29]

温度低于500℃时<100>型位错环为不可动型位错环,大量的<100>型位错环阻碍位错运动从而使材料发生辐照硬化

1/2<111>型位错环为可动型位错环,在应力作用下可分解生成<100>型位错片段,使材料发生硬化效应

而AlNbMoZrB合金中产生的辐照诱导缺陷大部分为1/2<111>型位错环,对力学性能的影响较小

3 结论

(1) 在AlNbMoZr基高熵合金中添加少量B元素可制备一种具有中子毒性的结构功能一体化高熵合金AlNbMoZrB

铸态AlNbMoZrB合金具有优异的力学性能

(2) AlNbMoZrB合金具有典型的树枝晶结构,枝晶区富集Mo、Nb和B元素为BCC结构基体相,而Al、Zr元素富集在枝晶间区,形成Al-Zr相及α-Zr相,B元素主要以间隙原子的形式固溶在基体中

(3) Kr离子辐照使AlNbMoZrB合金枝晶间区中的α-Zr相非晶化,而基体BCC相和Al-Zr相在常温和300℃均不发生相变

(4) Kr离子辐照使AlNbMoZrB合金产生大量位错环,辐照温度的升高使位错环的复合效应增强、体积密度降低和尺寸增大

AlNbMoZrB合金中的位错环对其力学性能的影响较小

参考文献

View Option 原文顺序文献年度倒序文中引用次数倒序被引期刊影响因子

[1]

Zhang P, Jiang L, Yang J X, et al.

Research progress in refractory high entropy alloys for nuclear applications

[J]. Mater. Rev., 2022, 36(14):1

DOIURL [本文引用: 1]

张 平, 蒋 丽, 杨金学 等.

核用难熔高熵合金的研究进展

[J]. 材料导报, 2022, 036(14):1.

[本文引用: 1]

[2]

Li T X, Lu Y P, Cao Z Q, et al.

Opportunity and challenge of refractory high-entropy alloys in the field of reactor structural materials

[J]. Acta Metall. Sin., 2021, 57: 42

[本文引用: 1]

李天昕, 卢一平, 曹志强 等.

难熔高熵合金在反应堆结构材料领域的机遇与挑战

[J]. 金属学报, 2021, 57: 42

[本文引用: 1]

[3]

Wang X J, Qiao J W, Wu Y C.

High Entropy Alloys: the new irradiation-resistant candidate materials towards the fusion reactors

[J]. Mater. Rev., 2020, 34(17):9

[本文引用: 1]

王雪姣, 乔珺威, 吴玉程.

高熵合金:面向聚变堆抗辐照损伤的新型候选材料

[J]. 材料导报, 2020, 34(17):9

[本文引用: 1]

[4]

Yong Z A, Ttz A, Zhi T B, et al.

Microstructures and properties of high-entropy alloys

[J]. Prog. Mater. Sci., 2014, 61:1

DOIURL [本文引用: 1]

[5]

Yan X H, Zhang Y.

Preparation and forming process of high-entropy alloy

[J]. J. Netshape Form. Eng., 2022, 14(1): 19

[本文引用: 1]

闫薛卉, 张勇.

高熵合金的制备成形加工工艺

[J]. 精密成形工程, 2022, 14(01): 19

[本文引用: 1]

[6]

He J Y, Liu W H, Wang H, et al.

Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system

[J]. Acta. Mater., 2014, 62: 105

DOIURL [本文引用: 2]

[7]

Tripathy B, Saha R, Bhattacharjee P P.

Microstructure and unusually strong recrystallization texture of the FCC phase of a cost-effective high-strength dual-phase AlCrFe2Ni2 high entropy alloy

[J]. Intermetallics, 2022, 145: 107559.

DOIURL

[8]

Gong Z J, Li C H, Li XY, et al.

Microstructure and phase transition during heat treatment of a new Cu rich high-entropy alloy

[J]. Journal of Netshape Forming Engineering, 2022, 14(2): 83

龚子杰, 李春辉, 李晓宇 等.

新型含Cu高熵合金的微观组织及热处理过程相变

[J]. 精密成形工程, 2022, 14(02): 83

[9]

Wang J, Huang W G.

Microstructure and mechanical properties of CrMoVNbFex high-entropy alloys

[J]. Chin. J. Mater. Res., 2016, 30: 609

[本文引用: 1]

王 江, 黄维刚.

CrMoVNbFex高熵合金微观组织结构与力学性能

[J]. 材料研究学报, 2016, 30: 609

[本文引用: 1]

[10]

Zka J, Jaroslav M, Vesel J, et al.

Microstructure and room temperature mechanical properties of different 3 and 4 element medium entropy alloys from HfNbTaTiZr System

[J]. Entropy, 2019, 21(2):114

DOIURL " />

In this study, single-phase NbTiZr and NbTiZr(MoTa)0.1 medium-entropy alloys (MEAs) were investigated for their use in biomedical implants. The alloys were prepared by arc melting, and were then cold-rolled, annealed, and characterized in terms of phase analysis, mechanical properties, fractography, and wear resistance. Both alloys showed a single body-centered cubic phase with superior mechanical, and tribological properties compared to commercially available biomedical alloys. Mo and Ta-containing MEAs showed higher tensile yield strength (1060 ± 18 MPa)) and higher tensile ductility (~20%), thus overcoming the strength-ductility trade-off with no signs of transformation-induced plasticity, twinning, or precipitation. The generalized stacking fault energy (GSFE) calculations on the {112}<111> slip system by the first-principles calculations based on density functional theory showed that the addition of less than 0.2 molar fraction of Mo and Ta lowers the GSFE curves. This behavior posits the increase in ductility of the alloy by facilitating slips although strength is also increased by solid solution strengthening. The wear resistance of both alloys against hardened steel surfaces was superior to that of commercial biomedical alloys. Thus, we concluded that NbTiZr(MoTa)0.1 MEA with good tensile ductility is a potential candidate for biomedical implants.

[13]

Dirras G, Gubicza J, Heczel A, et al.

Microstructural investigation of plastically deformed Ti20Zr20Hf20Nb20Ta20 high entropy alloy by X-ray diffraction and transmission electron microscopy

[J]. Mater. Charact., 2015, 108: 1

DOIURL

[14]

Senkov O N, Rao S, Chaput K J, et al.

Compositional effect on microstructure and properties of NbTiZr-based complex concentrated alloys

[J]. Acta. Mater., 2018, 151: 201

DOIURL

[15]

Niu P D, Li R D, Yuan T C, et al.

Research progress of high-entropy alloys by additive manufacturing

[J]. J. Netshape Form. Eng., 2019, 11(4): 51

[本文引用: 1]

牛朋达, 李瑞迪, 袁铁锤 等.

增材制造高熵合金研究进展

[J]. 精密成形工程, 2019, 11(04): 51

[本文引用: 1]

[16]

Xie H B, Liu G Z, Guo J J.

Effect of Zr addition on microstructure and corrosion properties of AlFeCrCoCuZrx high-entropy alloys

[J]. J. Mater. Eng., 2016, 44(6): 44

[本文引用: 1]

谢红波, 刘贵仲, 郭景杰.

Zr元素对AlFeCrCoCuZrx高熵合金组织及腐蚀性能的影响

[J]. 材料工程, 2016, 44(6): 44

[本文引用: 1]

[17]

Li T X, Miao J W, Lu Y P, et al,

Effect of Zr on the as-cast microstructure and mechanical properties of lightweight Ti2VNbMoZrx refractory high-entropy alloys

[J]. Int. J. Refract. Met. H., 2022, 103: 105762

DOIURL [本文引用: 1]

[18]

Hong D, Wang H B, Hou L G, et al.

Research progress of effect of interstitial atoms on high-entropy alloy's microstructure and properties

[J]. Nonferr. Metal. Sci. Eng., 2020, 11(6):7

[本文引用: 1]

洪 达, 王和斌, 侯陇刚 等.

间隙原子对高熵合金组织及性能影响的研究现状

[J].

有色金属科学与工程, 2020, 11(6):7

[本文引用: 1]

[19]

Zong Y, Hashimoto N, Oka H.

Study on irradiation effects of refractory bcc high-entropy alloy

[J]. Nucl. Mater. Energy., 2022, 31: 101158

[本文引用: 1]

[20]

Li Y, Zhang P, Zhang J, et al.

Oxidation behavior of AlCoCrFeNiSi high-entropy alloys at 1100

[J]. Corros. Sci., 2021, 190(1): 109633

DOIURL

[21]

Li G, Wen Y, Yu Z M, et al.

Effect of Al content on properties of CrFeNiAlxSi high entropy alloy

[J]. Chin. J. Mater. Res., 2021, 35(9): 712

[本文引用: 1]

李 刚, 温 影, 于中民 等.

Al含量对CrFeNiAl(x)Si系高熵合金性能的影响

[J]. 材料研究学报, 2021, 35(9): 712

[本文引用: 1]

[22]

Kang B, Kong T, Dan N H, et al.

Effect of boron addition on the microstructure and mechanical properties of refractory Al0.1CrNbVMo high-entropy alloy

[J]. Int. J. Refract. Met. H., 2021, 100: 105636

DOIURL [本文引用: 1]

[23]

Guo S, Ng C, Lu J, et al.

Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys

[J]. J. Appl. Phys., 2011, 109: 103505

DOIURL [本文引用: 1] class="outline_tb" " />

In this study, single-phase NbTiZr and NbTiZr(MoTa)0.1 medium-entropy alloys (MEAs) were investigated for their use in biomedical implants. The alloys were prepared by arc melting, and were then cold-rolled, annealed, and characterized in terms of phase analysis, mechanical properties, fractography, and wear resistance. Both alloys showed a single body-centered cubic phase with superior mechanical, and tribological properties compared to commercially available biomedical alloys. Mo and Ta-containing MEAs showed higher tensile yield strength (1060 ± 18 MPa)) and higher tensile ductility (~20%), thus overcoming the strength-ductility trade-off with no signs of transformation-induced plasticity, twinning, or precipitation. The generalized stacking fault energy (GSFE) calculations on the {112}<111> slip system by the first-principles calculations based on density functional theory showed that the addition of less than 0.2 molar fraction of Mo and Ta lowers the GSFE curves. This behavior posits the increase in ductility of the alloy by facilitating slips although strength is also increased by solid solution strengthening. The wear resistance of both alloys against hardened steel surfaces was superior to that of commercial biomedical alloys. Thus, we concluded that NbTiZr(MoTa)0.1 MEA with good tensile ductility is a potential candidate for biomedical implants.

[13]

Dirras G, Gubicza J, Heczel A, et al.

Microstructural investigation of plastically deformed Ti20Zr20Hf20Nb20Ta20 high entropy alloy by X-ray diffraction and transmission electron microscopy

[J]. Mater. Charact., 2015, 108: 1

[14]

Senkov O N, Rao S, Chaput K J, et al.

Compositional effect on microstructure and properties of NbTiZr-based complex concentrated alloys

[J]. Acta. Mater., 2018, 151: 201

[15]

Niu P D, Li R D, Yuan T C, et al.

Research progress of high-entropy alloys by additive manufacturing

[J]. J. Netshape Form. Eng., 2019, 11(4): 51

牛朋达, 李瑞迪, 袁铁锤 等.

增材制造高熵合金研究进展

[J]. 精密成形工程, 2019, 11(04): 51

[16]

Xie H B, Liu G Z, Guo J J.

Effect of Zr addition on microstructure and corrosion properties of AlFeCrCoCuZrx high-entropy alloys

[J]. J. Mater. Eng., 2016, 44(6): 44

谢红波, 刘贵仲, 郭景杰.

Zr元素对AlFeCrCoCuZrx高熵合金组织及腐蚀性能的影响

[J]. 材料工程, 2016, 44(6): 44

[17]

Li T X, Miao J W, Lu Y P, et al,

Effect of Zr on the as-cast microstructure and mechanical properties of lightweight Ti2VNbMoZrx refractory high-entropy alloys

[J]. Int. J. Refract. Met. H., 2022, 103: 105762

[18]

Hong D, Wang H B, Hou L G, et al.

Research progress of effect of interstitial atoms on high-entropy alloy's microstructure and properties

[J]. Nonferr. Metal. Sci. Eng., 2020, 11(6):7

洪 达, 王和斌, 侯陇刚 等.

间隙原子对高熵合金组织及性能影响的研究现状

[J]. 有色金属科学与工程, 2020, 11(6):7

[19]

Zong Y, Hashimoto N, Oka H.

Study on irradiation effects of refractory bcc high-entropy alloy

[J]. Nucl. Mater. Energy., 2022, 31: 101158

[20]

Li Y, Zhang P, Zhang J, et al.

Oxidation behavior of AlCoCrFeNiSi high-entropy alloys at 1100

[J]. Corros. Sci., 2021, 190(1): 109633

[21]

Li G, Wen Y, Yu Z M, et al.

Effect of Al content on properties of CrFeNiAlxSi high entropy alloy

[J]. Chin. J. Mater. Res., 2021, 35(9): 712

李 刚, 温 影, 于中民 等.

Al含量对CrFeNiAl(x)Si系高熵合金性能的影响

[J]. 材料研究学报, 2021, 35(9): 712

[22]

Kang B, Kong T, Dan N H, et al.

Effect of boron addition on the microstructure and mechanical properties of refractory Al0.1CrNbVMo high-entropy alloy

[J]. Int. J. Refract. Met. H., 2021, 100: 105636

[23]

Guo S, Ng C, Lu J, et al.

Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys

[J]. J. Appl. Phys., 2011, 109: 103505

![]()

Phase stability is an important topic for high entropy alloys (HEAs), but the understanding to it is very limited. The capability to predict phase stability from fundamental properties of constituent elements would benefit the alloy design greatly. The relationship between phase stability and physicochemical/thermodynamic properties of alloying components in HEAs was studied systematically. The mixing enthalpy is found to be the key factor controlling the formation of solid solutions or compounds. The stability of fcc and bcc solid solutions is well delineated by the valance electron concentration (VEC). The revealing of the effect of the VEC on the phase stability is vitally important for alloy design and for controlling the mechanical behavior of HEAs.

[24]

Takeuchi A, Inoue A.

Quantitative evaluation of critical cooling rate for metallic glasses

[J]. Mater. Sci. Eng., 2001, 304-306A: 446

[25]

Guo S, Liu C T.

Phase stability in high entropy alloys: Formation of solid-solution phase or amorphous phase

[J]. Prog. Nat. Sci-Mater., 2011, 21(6): 433

[26]

Griffiths M.

A review of microstructure evolution in zirconium alloys during irradiation

[J]. J. Nucl. Mater., 1988, 159: 190-218

[27]

Lefebvre F, Lemaignan C.

Heavy ion-induced amorphlsation of Zr(Fe, Cr)2 precipitates in Zircaloy-4

[J]. J. Nucl. Mater., 1989, 165(2):122-127

[28]

El-Atwani O, Esquivel E, Efe M, et al.

Loop and void damage during heavy ion irradiation on nanocrystalline and coarse grained tungsten: Microstructure, effect of dpa rate, temperature, and grain size

[J]. Acta. Mate., 2018, 149: 206

[29]

Arakawa K, Hatanaka M, Kuramoto E, et al.

Changes in the burgers vector of perfect dislocation loops without contact with the external dislocations

[J]. Phys. Rev. Lett., 2006, 96(12): 125506

Research progress in refractory high entropy alloys for nuclear applications

1

2022

声明:

“AlNbMoZrB系难熔高熵合金的Kr离子辐照损伤行为” 该技术专利(论文)所有权利归属于技术(论文)所有人。仅供学习研究,如用于商业用途,请联系该技术所有人。

我是此专利(论文)的发明人(作者)

847

编辑:中冶有色技术网

来源:毛建军,富童,潘虎成,滕常青,张伟,谢东升,吴璐

847

编辑:中冶有色技术网

来源:毛建军,富童,潘虎成,滕常青,张伟,谢东升,吴璐

举报 0

举报 0

收藏 0

收藏 0

反对 0

反对 0

点赞 0

点赞 0